By CHUCK HORNBROOK June 25, 2013

Just as it is necessary to have solar panels and inverters that are bankable, third-party owners of PV systems want a monitoring system that is bankable, as well as financially feasible.

One of the fastest-growing business models in distributed generation is the use of financing and third-party ownership for residential systems.

These models have been used for some time with commercial systems, but their use now accounts for more than 50 percent of all residential solar photovoltaic (PV) systems installed in the United States, according to Greentech Media. As with commercial systems, it is critical that these installations meet the needs of the host customer by delivering consistent solar kilowatt-hours. Because these solar PV systems are now financial instruments owned by a third-party financial institution, the PV fleet manager also needs to have consistent access for measuring solar kilowatt-hours produced and ensuring uptime. Unlike commercial systems, though, which amount to a few thousand installations annually, residential systems installations are in the tens of thousands each year. – BOLD

Using metering equipment that meets safety, reliability and accuracy standards becomes critical in these installations. The monitor needs to have a low cost as a percentage of the total installed costs, while also maintaining accuracy.

Ideally, a 5-kilowatt (kW) solar system would be monitored with the same monitoring system used for a 500-kW system, but in reality that is not financially feasible. Across one or two systems, a meter with 5 percent accuracy might make sense, but when it is thousands of systems, 4 to 5 percent can make a material impact on the financial payback of the installed PV system, even if all of the systems are 5 kW.

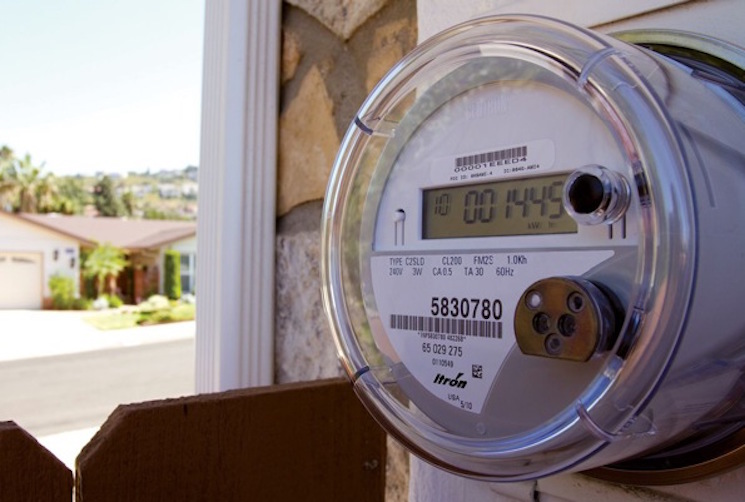

Just as it is necessary in this new financing paradigm to have solar panels and inverters that are bankable, third-party owners of PV systems want a monitoring system that is bankable, as well as financially feasible. One way to ensure that is by using a revenue-grade ANSI-certified meter with an accuracy level of 0.5 percent.

What’s Inside the Standard?

As stated on its website, the American National Standards Institute (ANSI) “oversees the creation, promulgation and use of thousands of norms and guidelines that directly impact businesses in nearly every sector: from acoustical devices to construction equipment, from dairy and livestock production to energy distribution.” ANSI is also the nation’s official representative of the International Organization for Standardization and sets electrical safety and operating standards for the United States. These standards have been adopted by several utilities in Canada, as Canada’s electrical system is inter- connected with that of the United States. These safety and operating standards address topics such as humidity, rain, voltage surge and others to ensure meters work safely and properly within certified operational parameters.

Acceptable performance criteria for devices used in metering fall under ANSI C12. C12 describes acceptable performance levels including accuracy and table reading format for AC watt-hour meters, demand meters, demand registers, pulse devices and auxiliary devices. It also includes information on related subjects, such as recommended measurement standards, installation requirements, test methods and test sequences. Temperature, humidity and UV light testing are also part of the testing to ensure accuracy and reliability for a piece of hardware that will be in the field for a long time under various conditions.

Accuracy is covered under ANSI C12.20 Class 0.2 and Class 0.5, with the class numbers representing the maximum percent metering error permissible at normal loads: 0.2 percent or 0.5 percent. Typical residential solid-state (or digital) electricity meters are of Class 0.5, where- as electromechanical meters in the past were typically built to the less stringent ANSI C12.1 standards. ANSI C12.20 Class 0.2 and Class 0.5 meters are considered to be “revenue grade,” meaning they are accurate enough for utility billing or gathering of revenue. These meters are required to continue metering electricity down to the low level of 0.1 ampere (24 watts).

In the case of solar PV systems, meters that are not ANSI C12.20 Class 0.2 or Class 0.5 compliant, or not revenue-grade, may under-calculate total generation. In addition, in the event of low energy production, these non-revenue-grade meters might record no energy production at all.

It’s About the Economics

So what does this mean for a solar fleet operations director or a solar installer looking to ensure the best monitoring system? Let’s analyze a solar fleet of 10,000 solar PV systems, for example. Over the course of one year for these 10,000 installed solar systems, the difference between 5 percent and 0.5 percent accuracy could equate to a difference of more than $400,000 if they are underreporting. (Calculation assumes average system size of 5 kW, 21 percent capacity factor and 11 cents per kilowatt-hour for solar generation.) This lost cash flow drops right to the bottom line.

Based on these economics, it is easy to under- stand why electric utilities insist on using ANSI

C12.20 meters. If they used anything less accurate, they would be in danger of collecting less revenue. Take into account other considerations such as the ruggedness, safety and reliability of the metering system, and one begins to realize why the electric utilities exert so much effort to ensure that this asset is safe, easy to install and accurate. Should it be any different for owners or managers of PV solar fleets?

Chuck Hornbrook is a senior product manager for smart grid solutions at Itron. He has more than 15 years of experience in the utility and technology industries. Prior to working at Itron, Hornbrook managed Pacific Gas and Electric’s distributed energy program. He has an MBA and an M.S. in environmental policy from the University of Michigan. Hornbrook can be reached at chuck.hornbrook@itron.com.

Chuck Hornbrook is a senior product manager for smart grid solutions at Itron. He has more than 15 years of experience in the utility and technology industries. Prior to working at Itron, Hornbrook managed Pacific Gas and Electric’s distributed energy program. He has an MBA and an M.S. in environmental policy from the University of Michigan. Hornbrook can be reached at chuck.hornbrook@itron.com.