By Trudy Forsyth and Frank Oteri October 29, 2013

Spirit Lake’s first turbine was installed in 1993 with a second one coming online eight years later. Photo: Spirit Lake Community Schools

Distributed wind is one solution that people — whether homeowners, small businesses, school districts or farmers — are using toward their goals of energy independence and economic benefit. This market, and the incentives available to it, allow the distributed wind industry opportunities to continually improve the technology and reduce costs in line with PV and other renewable technologies.

As of the end of 2012, the United States had a cumulative installed capacity of more than 812 megawatts of distributed wind turbines, according to the U.S. Department of Energy. These systems are typically found in areas with high electricity rates, good incentives (of course the federal investment tax credit will last until the end of 2016) and good wind resources. The following four examples showcase turbine installations at a school, a residence, a farm and a commercial business.

Spirit Lake School District

Spirit Lake, Iowa, is home to the oldest of our example turbines, with a large capacity for its time. Purchased and installed in 1993, Spirit Lake School District’s first wind turbine, a 250-kilowatt (kW) Wind World, had such positive benefits that eight years later the school installed a second wind turbine.

The initial 250-kW turbine was installed for $239,500 and powered the elementary school. The turbine was partially funded from a U.S. Department of Energy grant, with the remaining cost funded through a low-interest loan from the Energy Council of Iowa Department of Natural Resources.

The school district made the final loan payment in 1998 (3.5 years ahead of schedule), and the second wind turbine was installed in 2001 at a cost of $780,000. Project funding for the 750-kW NEG/Micon turbine included two loans provided by the Iowa Energy Center’s Alternative Energy Revolving Loan Program and the Iowa Department of Natural Resources.

David Dau, director of operations for the Spirit Lake Community School District, said that the turbines provide a resource for the school in a variety of ways. “The turbines have been used as an educational tool in the curriculum at various grade levels and subjects,” Dau said. “They’ve generated tax-free income from clean renewable northwest Iowa wind to improve education for the children of Spirit Lake Community School District.

“The wind turbines have also helped establish a pathway for added energy efficiency. The district is steadily converting its buildings to energy-efficient lighting, and the high school will be totally [served by] geothermal heating and cooling after the 2013 addition and renovation project,” Dau said.

Caldwell-Davis-Bassetti Ranch

Gwen Bassetti owns a 10-kW Bergey turbine in Goldendale, Wash., that was installed in September 2004. The turbine had a total installed cost of $40,521 and was funded through multiple sources, including project support from Northwest Sustainable Energy for Economic Development, a grant from the U.S. Department of Agriculture’s (USDA’s) 9006 program, the pre-purchase of green tags from the Bonneville Environmental Foundation and by the Bassetti family.

“The turbine has exceeded expectations, particularly on the maintenance level,” Bassetti said. “That was something that I was worried about. We didn’t have anyone here with expertise on it, but the turbine just keeps spinning around up there.”

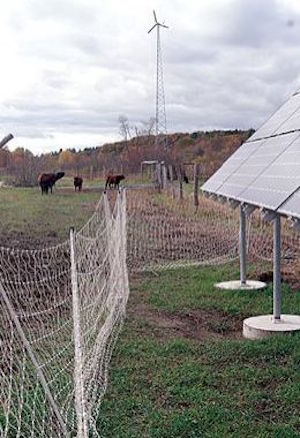

Cross Island Farms

Dani Baker and David Belding are co-owners of Cross Island Farms, a 102-acre certified organic farm on Wellesley Island in northern New York. In August 2011, they installed a 10-kW Bergey Excel wind turbine to minimize the overall environmental impact of their farm while expanding and enhancing its mission.

“We have a mission statement that talks about developing a farm that’s sustainable ecologically, economically and socially. Energy is a big issue in sustain- ability from all of those views,” Belding said.

Included in this nearly $135,000 renewable energy project were a 5.52-kW Sun- Power solar array and a 17-kW propane generator that were installed in September 2011.

The total project cost was partially funded through a USDA Rural Energy for America Program grant, a New York State Energy and Research Development Authority grant, and the federal investment tax credit.

During the first month of operation, the turbine helped reduce the farm’s energy bill by half. The following month, the combined systems reduced the farm’s utility bill to $16, the standard demand charge required by the local utility to connect to the grid. At the end of the year, Cross Island receives an annual reconciliation from their local utility, reimbursing them for any remaining electricity produced.

Byers Auto

The Byers Automotive Group installed two different wind turbines at two Ohio locations in 2010, establishing itself as a leader in renewable energy. The first turbine, a 100-kW Northwind 100, was dedicated at the Byers Mazda Subaru Dealership in Columbus in October 2010. The second turbine, a 15-kW Proven, was dedicated at the Byers Toyota Dealership in Delaware in November 2010.

The total cost to purchase and install the two turbines was approximately $600,000; it was partially funded through an Ohio Department of Development grant and a credit from section 1603 of the federal tax code.

George Kauffman, vice president of the Byers Automotive Group said, “Between the state grant and the federal credit, it 100 percent made this project feasible and doable in our eyes. Without one, I think it would have been a much harder pill to swallow to do it. The whole project overall was a pretty big risk for us.”

According to Kauffman, the incentives provided a measure of comfort, helping them to move forward with the project. “It all helped quite a bit.”

Trudy Forsyth and Frank Oteri are members of the ASES Wind Division. Forsyth is the division’s former co-chair.

One of two turbines, a 15-kW Proven, was dedicated at the Byers Toyota Dealership in Delaware, Ohio, in November 2010.