By Heather Alvis September 23, 2025

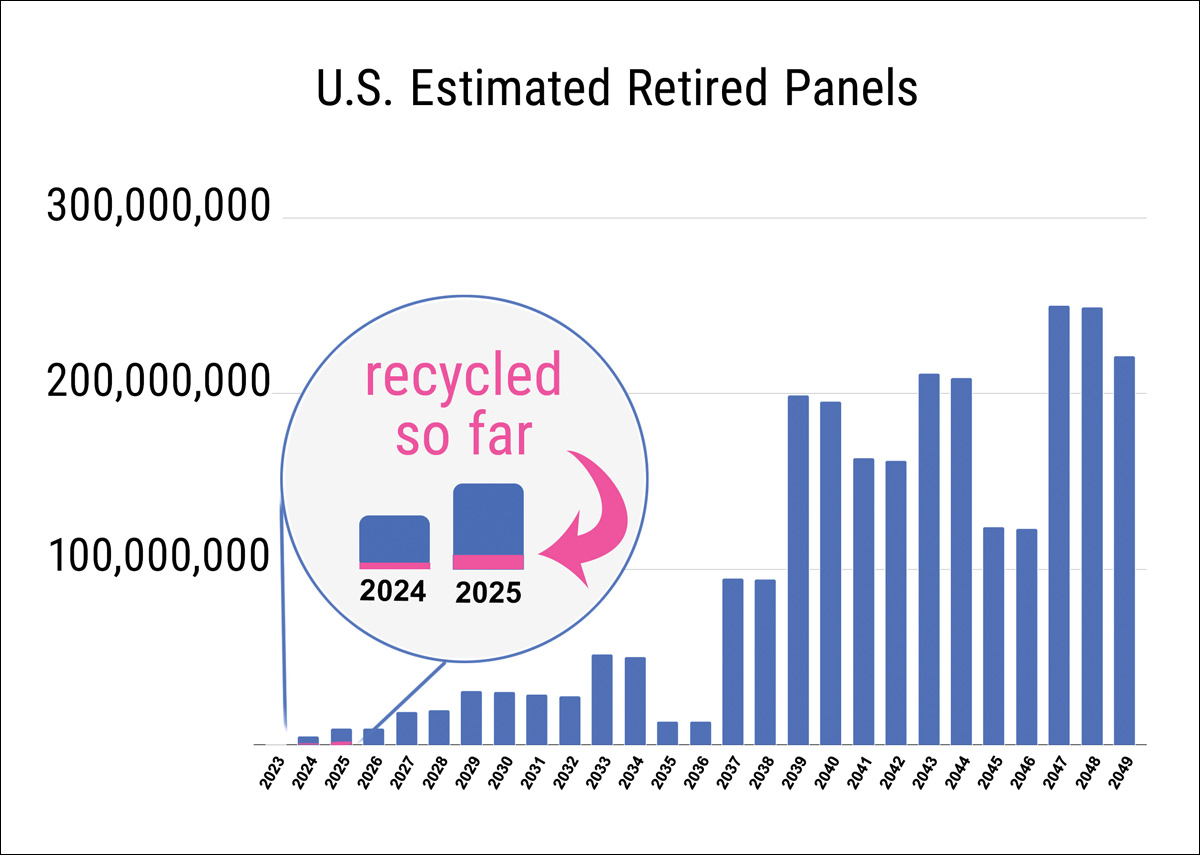

The projected waste from PV modules (blue bars) is far outweighed by the 10% that has been recycled to date. © Heather Alvis, data from NREL PV-Ice 2025

A Hard Reset for Clean Energy

The mood in solar has shifted. We’re no longer celebrating the surge of the Inflation Reduction Act; we’re managing the fallout of accelerated timelines, policy reversals, and mounting delays.1 Developers are racing against the clock. Projects are being held up by permitting bottlenecks and interconnection queues wrapped in red tape.

In such an environment, it makes sense to narrow your focus: land the project, meet your deadlines, and keep your team afloat. Most days, circularity isn’t on anyone’s radar. And that’s completely understandable.

But this is precisely the moment when we need to start thinking long-term.

We talk about the end of life in solar using words like “stranded,” “orphaned,” and “recovery.” As SEIA President Abby Hopper recently pointed out: “What’s up with all this traumatic language we use to describe solar near the end of its lifecycle?”

Instead, she writes, “we need to start now—investing in the infrastructure, standardized processes, and networks that will mean solar truly becomes the regenerative energy source we know it can be.”2

That’s the heart of circularity. It’s the commitment to build systems that keep materials in use—by design. It means planning ahead so panels can be repaired, reused, or recycled efficiently, without depending on last-minute decisions or landfill defaults. Circularity isn’t a single action. It’s an approach to building solar projects with their full life cycle in mind, from the first permit to final pickup.

The scale of what’s coming is hard to ignore. By 2030, the U.S. could see as many as 3 million tons of solar panels reach the end of life. By 2050, that number could top 160 million tons,3 enough to wrap around the Earth about 600 times. This represents a significant waste challenge and a $10 billion opportunity in recovered value.4

And it’s already underway. Panels are starting to come offline. If we don’t act now, before volumes spike, and before bad habits take root, we risk losing the trust this industry has worked so hard to earn.

It starts with data. Because you can’t reuse or recycle what you can’t find. And you can’t plan for the future if you don’t know what’s already in the field.

Waste Isn’t the Enemy—Misinformation Is

The conversation about solar waste is all over the map. Opponents use it as ammunition. Developers dread the permitting hurdles. Even climate advocates tiptoe around it, unsure whether talking about waste undermines the clean energy message.

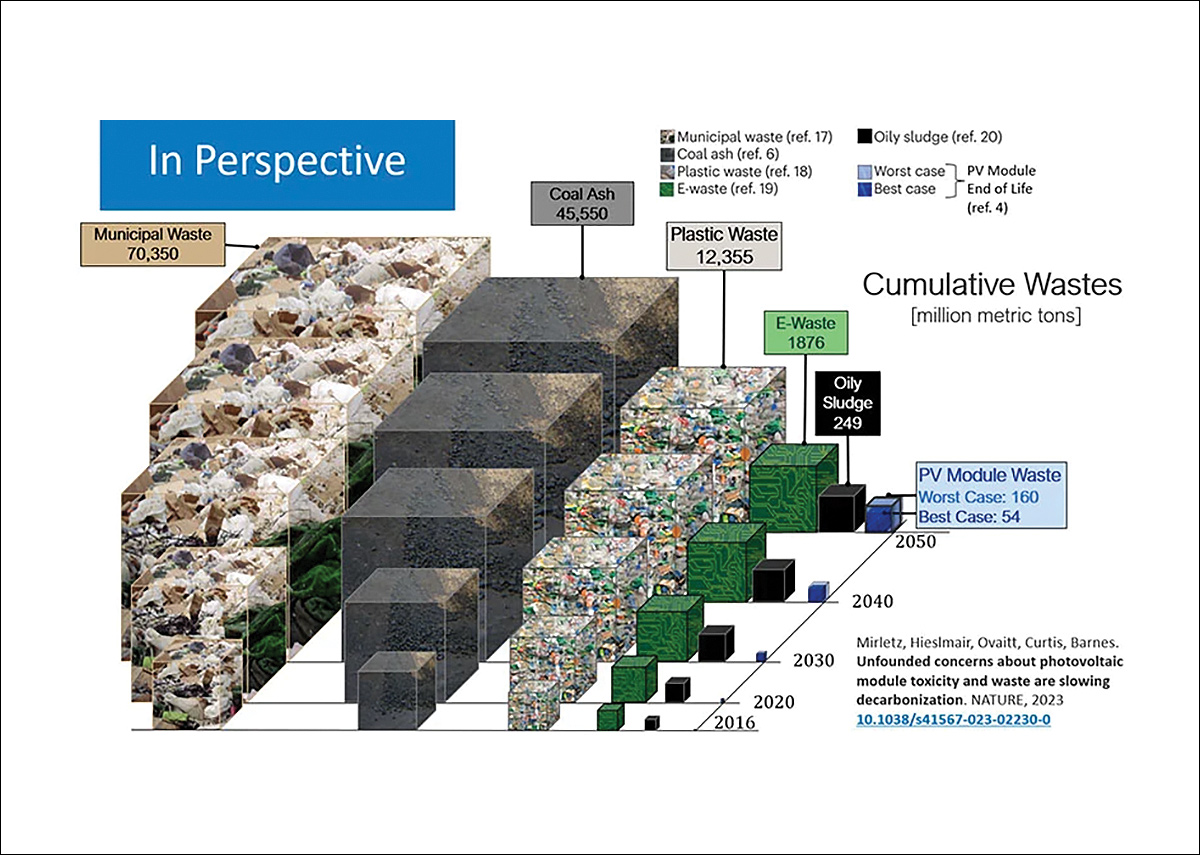

The data shows that solar waste is orders of magnitude smaller than the waste we’ve accepted for centuries from fossil fuels.5 According to NREL and multiple independent analyses, the mass of solar panel waste per megawatt-hour is hundreds of times smaller3 than the waste from coal or gas. And unlike coal ash or oil sludge, most of it is inert—glass, aluminum, silicon.

So why does the toxicity myth persist?

Because the public is still operating on outdated assumptions revolving around fear. According to the latest research from NREL, over 97% of PV modules on the market today are either crystalline silicon or cadmium telluride, with trace levels of lead or cadmium far below regulatory concern.3

The projected waste from PV modules (shown in blue on the right) is far outweighed by other types of waste. © Heather Mirletz, Silvana Ovaitt, Taylor Curtis, and Teresa Barnes, NREL, and Henry Hieslmair, DNV3

The Missed Opportunity: We Built a Grid Without a Map

Encouraging progress is emerging in the solar end of life (EOL) space. Engie’s “precycling” agreement with Solarcycle6 integrates recycling directly into the original power purchase agreement for over a million panels across four utility-scale sites. Comstock Metals7 has partnered with Virtus Renewables to offer full-service, zero-landfill decommissioning for developers.

EDP Renewables recently launched its Close the Loop program, a 360-degree sustainability initiative aimed at recovering 90% of waste from its global renewable energy assets by 2030.8 These initiatives are a step in the right direction. They show that the market is starting to respond, and that circularity is shifting from buzzword to blueprint.

But most of these arrangements are private, bilateral deals, and primarily structured for utility-scale projects. We haven’t seen their actual contracts, and we don’t know how they’ll perform over the full life of a 20-30 year solar project. If one party exits the industry, or changes strategy, it’s unclear who holds long-term responsibility for the panels. And even when these partnerships work exactly as planned, they represent just a fraction of the total material volume moving through the solar supply chain.

This patchwork approach makes sense in a competitive, capitalist market. But without a coordinated, industry-wide infrastructure, millions of panels will continue to fall through the cracks, particularly in the residential and commercial sectors, where there’s no clear ownership pathway after 10 or 15 years.

We need more than isolated success stories. We need a shared, transparent system; a digital map of what’s installed, where, and by whom. One that links manufacturer data to asset owners and EOL partners, enabling small-scale projects to benefit from the same circular logic as larger ones.

Currently, we’re trying to build a sustainable grid without a shared compass. And even the best intentions can’t scale without infrastructure to support them.

The Rising Tide of Regulation and the Need for Shared Infrastructure

In addition to developers and recyclers, PV manufacturers are now being asked to step up to manage waste.

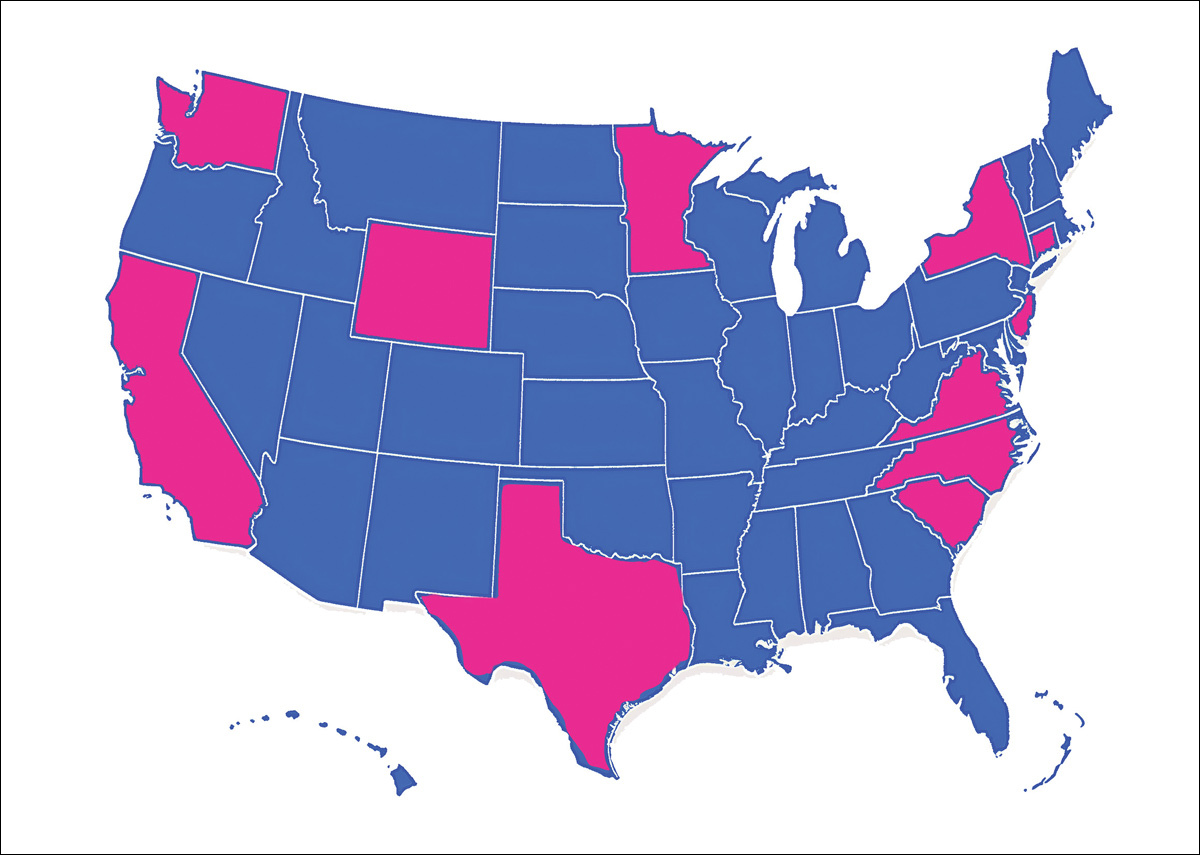

More than 13 states are working on, or have already passed, regulations mandating responsible disposal for retired solar panels. © Heather Mirletz

Across the U.S., states are introducing legislation9 that holds PV manufacturers accountable for EOL recovery. Washington State was the first to enact a mandatory takeback law10. Texas, Minnesota, New Jersey, Hawaii, and several other states are now following suit.11, 12, 13, 14 The intent is consistent: ensure that panels don’t wind up in landfills or roadside ditches.

However, while the laws share a similar spirit, each one differs slightly in design. Without coordination, this creates a fragmented compliance landscape that’s nearly impossible to manage, especially for manufacturers selling panels across multiple states.

And it’s not only manufacturers who need help. The agencies responsible for enforcing these laws are also operating in the dark. Most lack the technical systems or staff capacity to monitor recycling rates, verify responsible parties, or trace panels through multiple ownership transfers. This is where a national system could be transformative.

By sharing data across jurisdictions, while respecting privacy and commercial boundaries, we can build a unified foundation that supports compliance, enforcement, and policy alignment. It would reduce duplication of effort, support interstate logistics, and lower costs for everyone involved.

Because ultimately, it’s about adding more laws and building a system that makes the laws work.

Building the Circular Nervous System

If solar is the skeleton of the clean energy economy, then data is its nervous system. It’s what allows the industry to sense, respond, adapt, and heal.

In the context of EOL solar, that means tracking, not just for tracking’s sake, but to unlock entirely new forms of value and coordination. Imagine a system where every panel installed is assigned a digital identity, including its make, model, wattage, date of manufacture, and location. This information lives in a secure, shared database. As panels change hands, their records update. When performance drops or decommissioning is planned, the system flags it. Owners are notified of drop-off locations. Reuse projects scan inventory and match panels with schools or nonprofits in need. Recyclers know what’s coming months in advance.

Manufacturers gain visibility into where their products end up and what happens to them. This supports not only compliance with state laws, but internal reporting, brand trust, and closed-loop material sourcing. Regulators gain the ability to verify stewardship plan claims with actual weights, photos, and route logs, rather than relying on a mismatch of PDF uploads, handwritten form responses, and spreadsheets.

None of this is hypothetical. We already have the technology. QR codes. Blockchain. GPS. Public-private APIs. What’s missing is the connective layer that binds it all together: a national, manufacturer-agnostic, and recycler-agnostic system that tracks solar assets throughout their lifecycle.

We don’t need to mandate a single solution. We need to standardize the architecture so that different tools can speak the same language. That way, startups, states, recyclers, and manufacturers can plug in and still see the same map.

In practice, this doesn’t just help recyclers. It helps reduce shipping costs, minimize emissions, and ensure that second-life panels go where they’re needed most. It transforms circularity from an environmental checkbox into a real-time operational advantage.

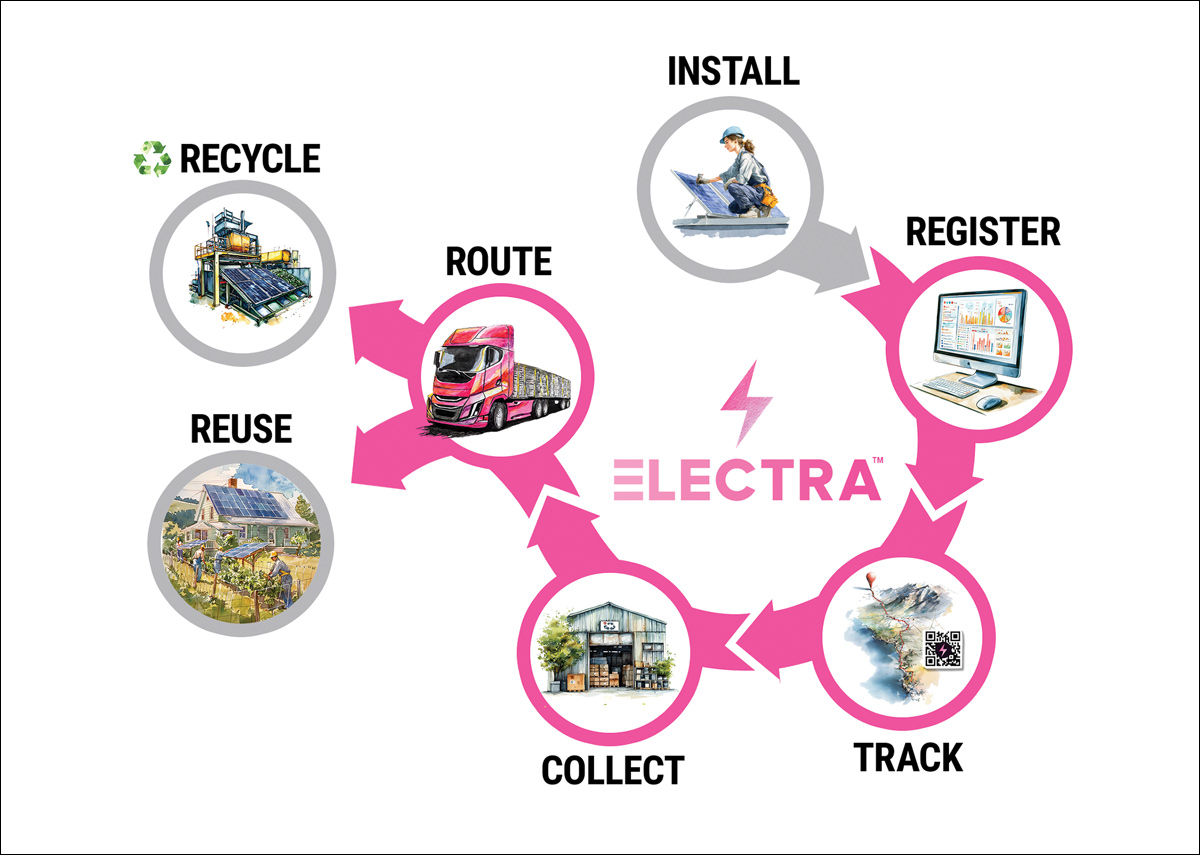

Electra is designed to manage the data tracking, collection, and reverse logistics of retired solar panels, routing them for reuse and recycling. © Heather Mirletz

It Has to Be Easier Than the Landfill

Technology alone won’t solve this. Systems don’t work unless people use them.

And when it comes to waste, convenience is king. One study found that 66% of Americans15 would rather throw a product away than recycle it if the recycling option isn’t easy or obvious. We can’t guilt people into doing the right thing; we have to make it the default.

For solar, this means designing systems that offer real benefits before the panels reach the end of their life. Registration should be seamless, ideally, part of the installation process. But beyond that, what if registering your panels gave you access to discounts on other clean energy upgrades, or rewards for participating in reuse or repair programs?

What if panel owners received real-time solar irradiance and weather forecasts tailored to their specific installation, helping them optimize performance and plan maintenance? What if we could offer insights based on the exact make, model, and local conditions of their system, such as when degradation is likely to start, or how their output compares to similar systems nearby?

These are not hypothetical. They’re achievable with data we already collect, or could collect, with minimal friction.

More importantly, these incentives turn registration into more than a compliance checkbox. They become a gateway to deeper engagement with clean energy. For local governments, utilities, and energy aggregators, this opens new opportunities to build trust, encourage stewardship, and reach underserved users.

We often assume because solar systems are high-tech, the solutions have to be complex. But the opposite is usually true. When we design for the edge case—the rural owner with no installer record, the landlord who inherited a leased system, the decommissioned school project—we create robustness that benefits the entire chain.

In the race to deploy clean energy, we optimized for speed and scale. Now we need to optimize for return and recovery. That starts by making the responsible thing easier, smarter, and more rewarding than doing nothing at all.

Because circularity doesn’t fail when systems break. It fails when people opt out.

A New Kind of Grid Integrity

When we talk about grid integrity, we usually mean uptime, reliability, and energy security. But what about material security? What about the traceability of assets, the resilience of our supply chains, and the ability to respond to change, not just at the circuit level, but at the system level? For circularity to become mainstream, we must first establish data collection and visibility.

To secure the solar economy in the long term, we need more than just panels on rooftops and in the field. We need intelligence embedded across the value chain—systems that track products across their lifecycle, verify claims, reduce logistical friction, and enable recovery without reinventing the wheel every time.

This is where a platform like Electra comes in, as a real-world attempt to address these challenges holistically. Electra is being designed as a national Solar Panel RegistryTM and Product Stewardship Network.TM Its goal is to:

- Track every panel from installation through reuse or recycling

- Digitally manage takeback fees, reverse logistics, and compliance

- Provide real-time reports to manufacturers, recyclers, and regulators

- Offer meaningful insights and benefits to panel owners throughout the panel’s life

By remaining manufacturer-agnostic and recycler-neutral, the system is designed to bridge fragmented state policies and support a circular supply chain that works across brands, geographies, and use cases.

Industry alignment is beginning to take shape. Solar Energy Industries Association’s (SEIA) recently released Circular Economy Roadmap for the Solar Industry outlines a multi-stakeholder framework for managing solar materials throughout their lifecycle, from design to deployment to EOL.16 It reinforces the idea that circularity can be both environmentally responsible and economically viable. What we need now are real systems that bring this vision to life on the ground. Electra’s registry is one example of how to do that.

This kind of infrastructure helps us prepare for future waste and strengthens our position in the global clean energy economy. It enables domestic manufacturers to recover high-value materials. It gives state agencies the tools to enforce policies effectively. It lowers barriers for small installers and community-scale projects. And it improves confidence in solar, not just as a clean energy source, but as a clean system.

For developers and distributors, this kind of infrastructure means simpler permitting, easier compliance reporting, and stronger long-term customer relationships. It’s a value-add that drives competitiveness, too.

Circularity is grid integrity. And data is the conduit that makes it all work.

Let’s Finish What We Started

Solar remains the best shot we’ve got at a livable, equitable future. But we can’t afford to build that future on half-finished systems.

We’ve done the hard work of scaling this industry, overcoming skepticism, improving affordability, surviving trade battles, and proving that clean energy can compete on its own terms. Now it’s time to build the scaffolding that makes that growth sustainable. That means planning for the end from the very beginning.

A circular solar economy won’t happen through one-off contracts or siloed legislation. It will take shared infrastructure. Shared language. Shared data.

We’re not starting from scratch. We have working models. We have motivated stakeholders. We have promising policies and active pilot projects. What we need now is alignment, a coordinated effort to integrate fragmented efforts into a functional, interoperable system.

If we do it right, we’ll do so much more than eliminate waste. We reduce emissions. We strengthen domestic supply chains. We create jobs. We build trust.

And we tell a new story about clean energy, one where integrity is measured not just in megawatts, but in what happens after the panels stop producing.

Circularity is about finishing what we started.

About the Author

Heather Alvis is the founder of Electra, a solar circularity startup, and an American Council on Renewable Energy (ACORE) Accelerate fellow. She is a member of the American Solar Energy Society and a finalist in the DOE’s Solar Prize competition, and a semi-finalist in the Re-X Before Recycling Prize.

Sources

- https://tinyurl.ee/qGCsi

- https://tinyurl.ee/gJgtX

- https://tinyurl.ee/CLXdX

- https://tinyurl.ee/fRvJb

- https://tinyurl.ee/CLXdX

- https://tinyurl.ee/pZImC

- https://tinyurl.ee/FIuwz

- https://tinyurl.ee/gHVSO

- https://tinyurl.ee/Wpjpt

- https://tinyurl.ee/lAxjK

- https://tinyurl.ee/DExIQ

- https://tinyurl.ee/PZEAp

- https://tinyurl.com/2npbvmw7

- https://tinyurl.com/5p3j6jb8

- https://tinyurl.ee/VaWpO

- https://tinyurl.com/tb98hsfn