By Christopher Medary September 22, 2023

Billets of aluminum are stacked in a factory. (Credit: Funtay)

As communities around the world transition to the green economy, one thing becomes increasingly clear — the shift to renewable technologies requires extraction. Instead of extracting coal, oil, natural gas and tar sands, we turn to lithium, cobalt, chromium, neodymium, and a plethora of other elements commonly deemed ‘critical minerals.’

Though the list of elements varies somewhat between countries and different organizations such as the International Energy Agency,1 the European Union2 and the International Renewable Energy Agency,3 all entities agree that these materials enable the function of our complex industrial society.

Often obscure, with hard-to-pronounce names, and produced in far-away places, myriad metals facilitate the function of laptops, phones, batteries, vehicles and industries. Interestingly, scaling up production of common metals presents a different set of challenges than scaling up production of other critical minerals such as dysprosium or platinum.

This article presents a brief introduction to aluminum and its importance in our economy, its uses and demand within renewable technologies, and the ongoing environmental and social costs of aluminum production.

Aluminum is ubiquitous. As you read this, it’s likely that you’re already touching it on your laptop or phone. If you’re not already touching aluminum, it’s certainly within arm’s reach — in the frame of a nearby window, in your car, in your appliances, in the structure of your home and office, or in food and drink packaging.

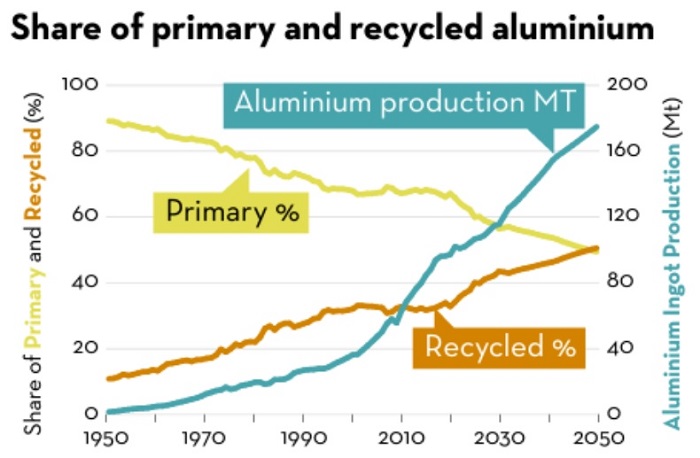

In this way, aluminum differs significantly from other critical minerals. It’s not rare, it’s commonplace. We already depend on it in mass quantities — over 68 million tons and 39 million tons of primary and recycled aluminum respectively in 20224, 5 — and hope to nearly double volumetric production by 2050.6

Aluminum is considered a high-impact and cross-cutting material for the renewable energy transition by the U.S. Agency for International Development7 and the World Bank.8 It is required for most renewables technologies — solar panels, batteries, wind turbines and electric vehicles — and thus will see a significant increase in production regardless of what mitigation pathway we pursue to achieve a 2°C temperature-rise world by 2100.9

The vast majority (87%) of the increase in demand due to renewables stems from solar arrays, and specifically from their framing and wiring components.10

At this point, you may be wondering why aluminum is such a big deal. How can the lightweight, strong, near-infinitely-recyclable metal, with a well-established production process and a history of sustainability leadership, be an issue for the renewable energy transition? Why does aluminum fly under the radar in the public sphere compared to lithium brines11 or artisanal cobalt mining?12

The answer to these questions revolves around primary aluminum production and its principal ore, bauxite. We’ll start with energy consumption and greenhouse gas emissions before moving on to human rights violations.

To make primary aluminum, three steps must occur: bauxite extraction, alumina refinement and aluminum smelting. This occurs on a global scale and includes mining sites, refinement facilities, smelters and trade routes.

Greenhouse gas emissions within the aluminum industry represent a major environmental impact and a significant contributor to the climate crisis.13

These emissions come from eight significant sources:

- combustion of fuel and electricity use for mining

- refiner use of industrial heat, steam and electricity

- production of other materials used in refining and smelting

- use of fossil fuel-based electricity to power electrolytic smelting

- emissions of direct CO2 from electrolysis

- energy to generate heat and steam during fabrication

- transportation to different sites for manufacturing and retail

- processing and disposal of waste14

It is unfortunate but true that production of a material intended to reduce greenhouse gas emissions is itself a major source of such emissions. The world’s aluminum smelters consume about 3.5% of total global electric power.15 Of course, a considerable portion of those emissions come from coal-powered smelting operations.16

How can we transition to clean electricity for aluminum smelters if aluminum is required in large quantities for solar panels? Hydropower and potentially geothermal, wind or nuclear could work but will have tradeoffs of their own. Moreover, because the energy requirements are so high for smelting, developing renewable power projects to meet those needs represents a major infrastructural endeavor.

The remainder of aluminum’s environmental and social impacts stem from its primary ore, bauxite. Inherently, the environmental impacts and social impacts are inextricably linked. We will approach these intersectional issues with two examples: bauxite mining and red mud.

Though aluminum hydroxides — bauxites — exist all over the world, relatively few deposits exist with aluminum concentrations high enough to justify extraction. A quick look through United States Geological Survey data presents a few geological realities.

- Five countries account for roughly three quarters (73%) of global bauxite reserves: Guinea (23%), Vietnam (18%), Australia (17%), Brazil (8%) and Jamaica (6%).

- Four countries are responsible for the majority (81%) of global bauxite production: Australia (27%), China (24%), Guinea (22%) and Brazil (8%).

- A few countries — Indonesia, Jamaica and Vietnam — have major resources but remain relatively undeveloped in terms of bauxite production.17

Bauxite mining is similar to other large-scale open-pit mining operations. It requires deforestation, blasting and excavation beyond 10 meters below the surface.

A Guinean Ministry of Mines-commissioned study estimated in 2019 that over the next 20 years, bauxite mining will eliminate 858 square kilometers of agricultural land and more than 4,700 square kilometers of natural habitat, an area six times bigger than New York City.18

Indeed the scale of impact is vast, is planned in decades, and irreversibly harms people living traditional livelihoods — subsistence farming and fishing and livestock rearing — in Brazil, Guinea and Australia.

In Guinea, 13 communities within or near Compagnie des Bauxites de Guinée’s Sangaredi operation noted several violations of international performance standards. Communities cite a failure to avoid and minimize displacement, including a lack of consultation prior to economic and environmental disruption, disruption of local livelihoods, failure to compensate for predicted and unpredicted impacts, reductions in access to water, and quality of life concerns associated with air and noise pollution.19

The case of Brazil follows that of Guinea. Bauxite mining irreversibly harms Quilombola and riverine communities within the state of Pará. For example, indigenous leaders claim genocide. Local researchers state, “Material full of lead, cadmium and aluminum is still there [in the rivers] and people are still drinking this water and eating fish from it.” The communities report undrinkable water that holds kaolin or caustic soda, elimination of fish stocks, and the associated collapse of local food sources.20

Though major mining companies such as Alcoa or Norsk Hydro report economic reinvestment in the region, locals say that the majority of economic opportunity has flowed to far-away urban centers and the economic benefits to rural communities are quite limited.21

In addition to the direct bauxite mining impacts, red mud drives a myriad of negative outcomes.

The Bayer process produces not only alumina from bauxite ore, but also an undesired byproduct called red mud. It contains toxic heavy metals. Its high alkalinity makes it extremely corrosive and damaging to soil, water and biota, creating a huge challenge for such disposals.22

The typical disposal method for red mud used in industrial alumina operations involves discharging it as a slurry into holding ponds or dams.23 But red mud does not go away. It is simply in a form of storage or confinement that can ultimately fail.

If red mud leaches from its storage area, whether by groundwater infiltration or large rain events, its high alkalinity and chemical composition damage water, soils and air of the surrounding area. The most infamous of these types of incidents occurred in Ajka, Hungary in 2010, though incidents have been recorded as far back as 2002.24

More than 150 million tons of bauxite residue are produced every year. The majority of this highly toxic waste is deposited as landfill. The total stockpile of red mud exceeds 3,500 million tons.25 That’s quite a lot of hazardous material to be storing near communities or anywhere.

So, where do we go from here? Aluminum, along with most other critical mineral extraction, represents the cutting edge of neocolonialism. Large corporate mining enterprises devastate indigenous and rural communities around the world to extract natural resources, leaving peril in their wake.

When framed in this light, primary aluminum becomes a second-choice material in terms of energy requirements, greenhouse gas emissions and social impact. Thus, major improvements must be made in collection and recycling capacity.

The renewables industry should minimize its use of primary aluminum as much as possible to abate the negative social and environmental impacts of its production. Solar-panel manufacturers should prioritize recycled aluminum for their framing where possible.

Moreover, developmental decisions need to consider material and energy realities. Aluminum-recycling facilities could be considered a priority to receive onsite renewables first, as they could facilitate the production of further renewables.

All aluminum experts posit that we will need to maintain some primary aluminum production capacity to meet climate goals, as recycled aluminum doesn’t have all the same properties as primary aluminum. Recycled materials’ strength can be compromised and can be unsuitable for some car components or for load-bearing construction.

The other aspect is aluminum demand.

At present, our global recycling rate of aluminum is roughly 75% for end-of-use products and nearly perfect recycling in manufacturing processes. Combined, this material comprises our entire global recycled-aluminum stream, over 35,800 kilotons annually.26

So even if we reached 100% recycling rates for end-of-use aluminum, we would still need to meet the majority of our aluminum demand with primary aluminum. Industry models show maintaining our current primary aluminum production volumes through 2050, growing demand even in aggressive climate-action scenarios.27

So the question becomes: How can we eliminate the adverse effects of historical aluminum production? From where I sit, there is no middle path here. Surface mining in biodiverse, culturally rich regions will irreversibly change those landscapes.

Though there is some promise, such as Brazil’s responsible mining initiative,28 I remain skeptical. The worst red-mud spill in Brazil’s history occurred less than a year after the publication of that report.29 There have been more recent reports of contamination.30

Even though red mud might have some promise in various applications, the research remains in its infancy. Certainly the possibility of reusing an industrial byproduct is positive, but does it justify continued expansion of bauxite mines?

Scaling red-mud reuse would require development of its own, in addition to increased bauxite mining.

The answer may be, as with so many environmental issues: Decrease the material throughput of our society. Use less. Most aluminum-demand models available present the familiar hockey-stick graph of the 20th century.

Critical minerals demand critical thought — about their uses, energy demands and societal tradeoffs. Without robust action on nuanced aspects of renewables technologies, we could repeat our past mistakes.

Sources

- https://tinyurl.com/IEAcriticalminerals

- https://tinyurl.com/EUcriticalminerals

- https://tinyurl.com/IRENAcriticalminerals

- https://tinyurl.com/IAIstats

- https://tinyurl.com/alucycle

- https://tinyurl.com/IAIflowmodel

- https://tinyurl.com/USAIDmining

- https://tinyurl.com/WorldBankcriticalminerals

- https://tinyurl.com/USAIDmining

- https://tinyurl.com/WorldBankcriticalminerals

- https://tinyurl.com/saltonsealithium

- https://tinyurl.com/cobaltredbook

- https://tinyurl.com/WEFaluminum

- https://tinyurl.com/primaryingot

- https://tinyurl.com/smelterenergy

- https://tinyurl.com/primaryingot

- https://tinyurl.com/USGSbauxite

- https://tinyurl.com/HRWcars

- https://tinyurl.com/HRWguinea

- https://tinyurl.com/mongabay1

- https://tinyurl.com/mongabay2

- https://tinyurl.com/Red-Mud

- https://tinyurl.com/Red-Mud2

- https://tinyurl.com/Ajka-spill

- Ibid.

- https://tinyurl.com/alucycle

- Ibid.

- https://tinyurl.com/BrazilResponsibleMining

- https://tinyurl.com/mongabay1

- https://tinyurl.com/mongabay2

About the Author

Christopher Medary holds a Master’s of Environmental Management degree from Western Colorado University, where his research focused on the energy transition. A systems thinker, he works on diverse projects internationally for grid resilience, circular economy and climate action. He wrote this article as a research fellow at Sustainable Development Strategies Group.

Hey, I got an idea. Much of the metal resources we need for the RE revolution is on IC (internal combustion) wheels. We need a “bounty” on IC’s, to drive them into the smelters (powered by RE electricity). I read somewhere that 70% of steel is from recycling. What about aluminum? What about all the steel in the oil and gas rigs and pipelines. Got to be a lot of what we need? How much is on wheels? Calculations? Happy Holiday!

Thanks for your comment!